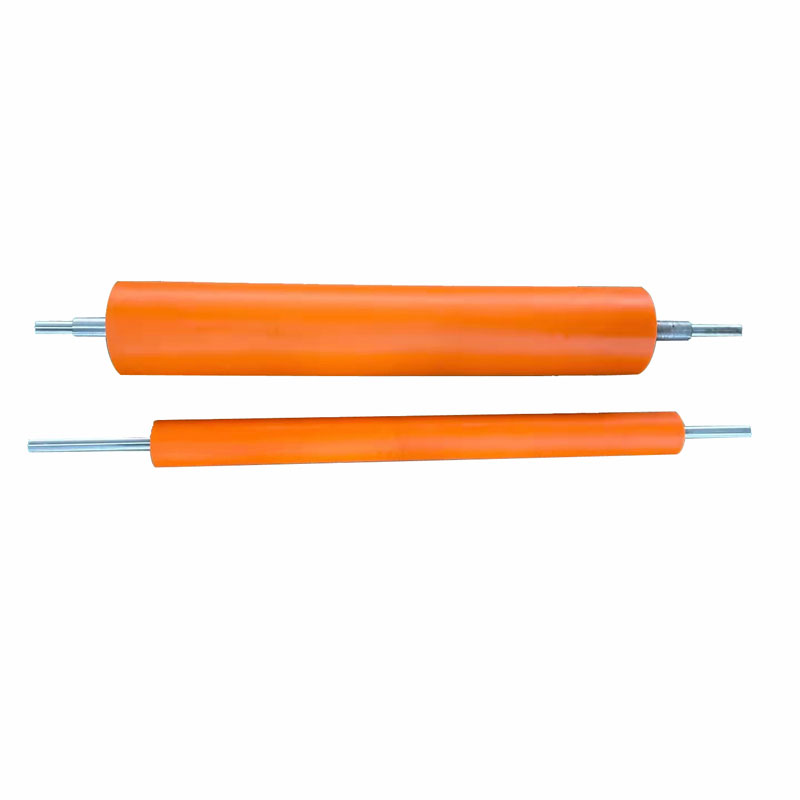

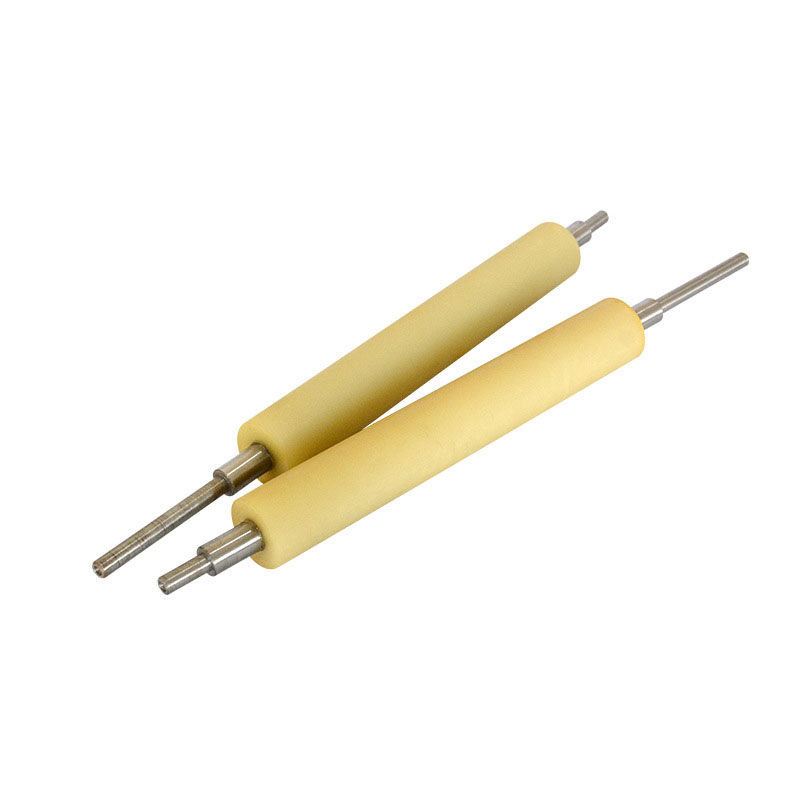

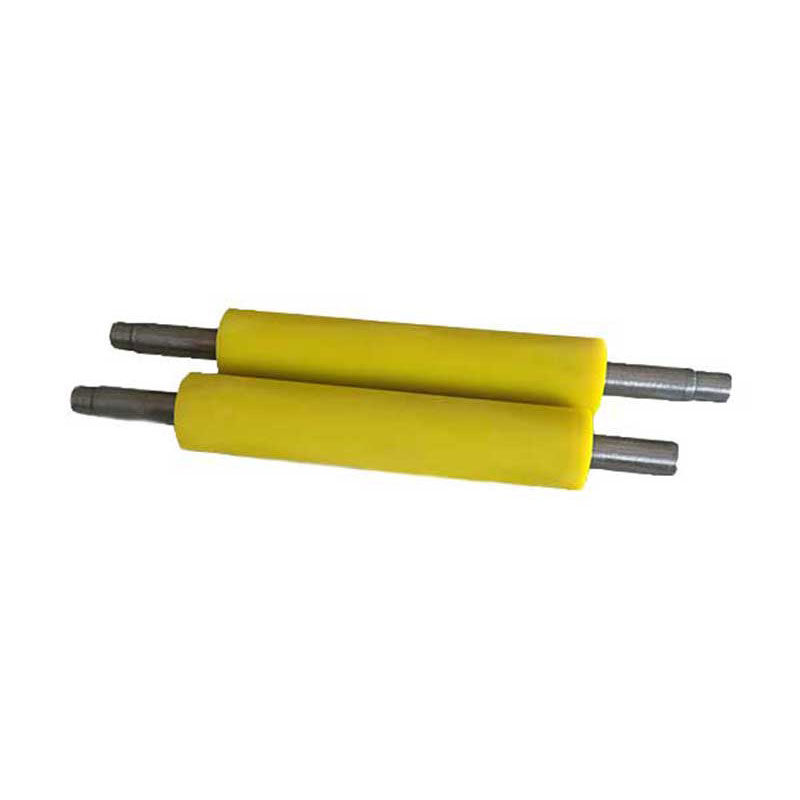

Polyurethane Conveyor Rollers

- Min.Order QTY: 50piece

- Packaging: Carton or Plywood Box

- Delivery Time: 15 Working Days

- Port: Shanghai/Ningbo

- Payment Terms: T/T,Western Union,Paypal

- Specifications

Polyurethane Conveyor Rollers – Urethane Conveyor Rollers

Polyurethane conveyor rollers offer very long service life with abrasion-resistant and solvent-resistant roller with very good noise abatement properties. inner core of conveyor rollers can be aluminum or solid steel, pipe steel, bearing, shaft, threaded stud etc. and outer coated polyurethane to protect metal roller, and help belt drive systems to operate longer.

We can manufacture a new roller and can also strip out previously coated and recover any existing urethane conveyor rollers. the cost of refurbish polyurethane conveyor rollers is less than buying one new!

PU Conveyor Rollers Application

Polyurethane conveyor roller has widely used in ship vessels, material handling system, logistic conveyor and mining applications.

Type of Polyurethane Roller we manufacture

- Drive rollers

- Idler rollers

- Conveyor rollers

- Feed rollers

- Load rollers

- Guide rollers

- Support rollers

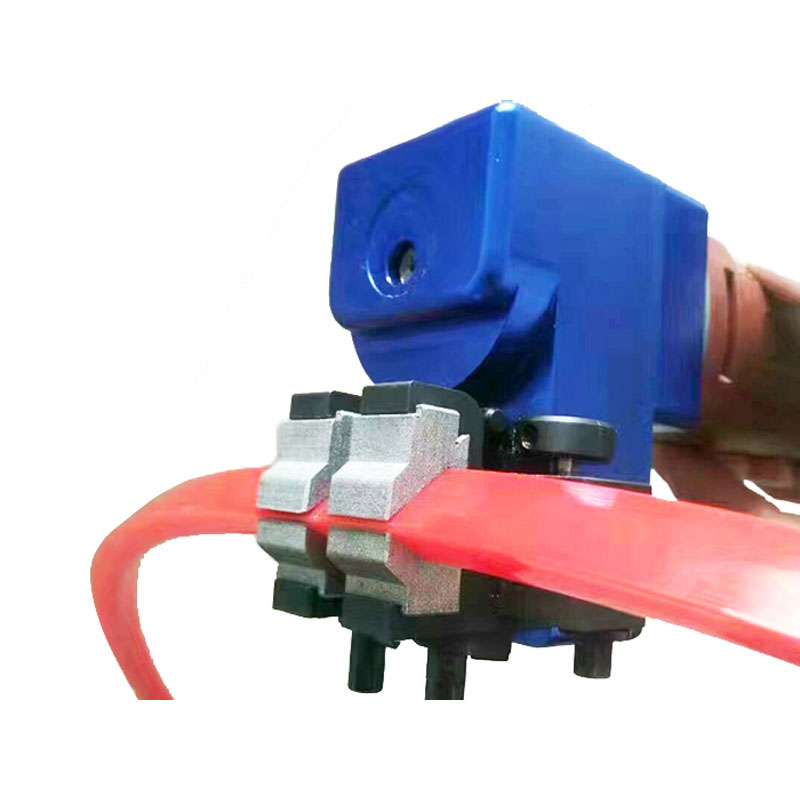

- Pinch roller/Pressure roller

We offer complete manufacturing capability for the cores metal required for your conveyor roller and provide one-stop shopping for custom cast polyurethane conveyor roller. The machining equipment includes CNC Mills, CNC Lathes, Grooving Lathe Machine and grinders. Secondary equipment includes sheet metal, welding, grinding, automated cutoff, broaching and more.

We can help you choose the right polyurethane roller as according to your load, speed, and application needs, and coated polyurethane on roller at exact thickness and specification required by your technical drawing. Contact us for further needs regard Custom Polyurethane Conveyor Rollers.

Tag:conveyor rollers , polyurethane conveyor rollers , polyurethane covered rollers , Polyurethane Rollers , PU Conveyor RollersDevelop & Produce Polyurethane Products

We focus on the needs of all our customers and continue to develop innovative products based on our experience and expertise. This allows us to continuously expand our product line to meet the needs of different customers.

Pulisen have the capability and facilities to produce any kind of Urethane product from 30A to 75D, in any shape, size or color.at the same time,we can custom polyurethane products from your drawings or sketches to meet your industrial application.

- Most of our standard products are in stock for fast delivery

- If you are in need of a custom cast urethane products,contact us today for more information,we will be happy to assist you.