Polyurethane Rollers

Pulisen provide high-performance polyurethane roller to meet the demands of many industrial applications.

We also offer custom urethane roller and re-coat roller services. strips the old rollers and bond with a new polyurethane coating. our PU rollers are, or can be:

* Guide rollers

* Drive rollers,

* Conveyor rollers,

* Idler rollers

* Pipe rollers

* Feed rollers,

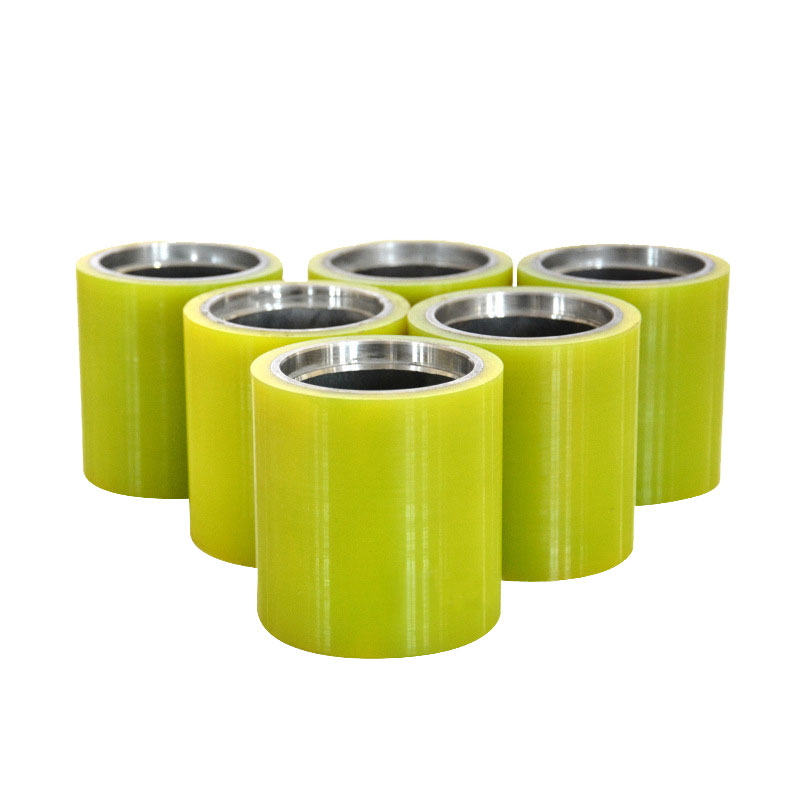

* Polyurethane rollers with bearings

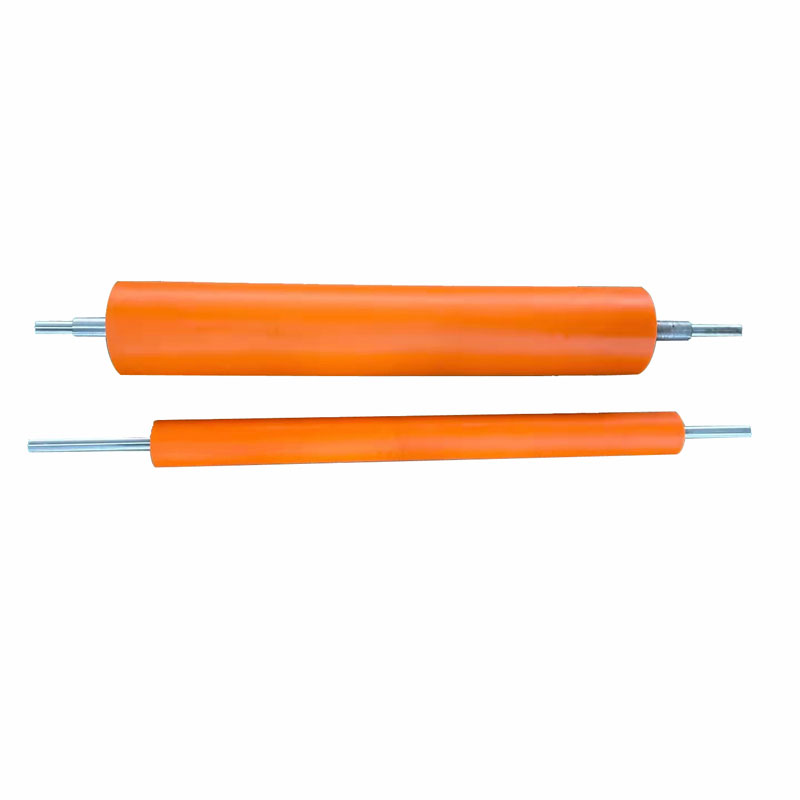

* Urethane rollers with shaft and more…

Custom Polyurethane Rollers & Cast Urethane Wheels

As polyurethane rollers manufacturer, We have more than 10 years production experience in this field. we providing the best roller solutions for our customers in various industries.

we focus on the manufacturing of refurbish polyurethane rollers, conveyor rollers, AGV stacker roller, Grooved rollers, belt roller, Guide Roller, silicone rubber roller, Heavy duty roller, carbon Fiber guide rollers and precision rollers. As the key parts of material handling and pulley system, rollers are used in digital printer, converting, textile, logistics conveyor systems, plastic film, paper-making, glass conveyor, mining machines, filter and other industries.